TECHNOLOGY

APPLICATIONS

MARKETS

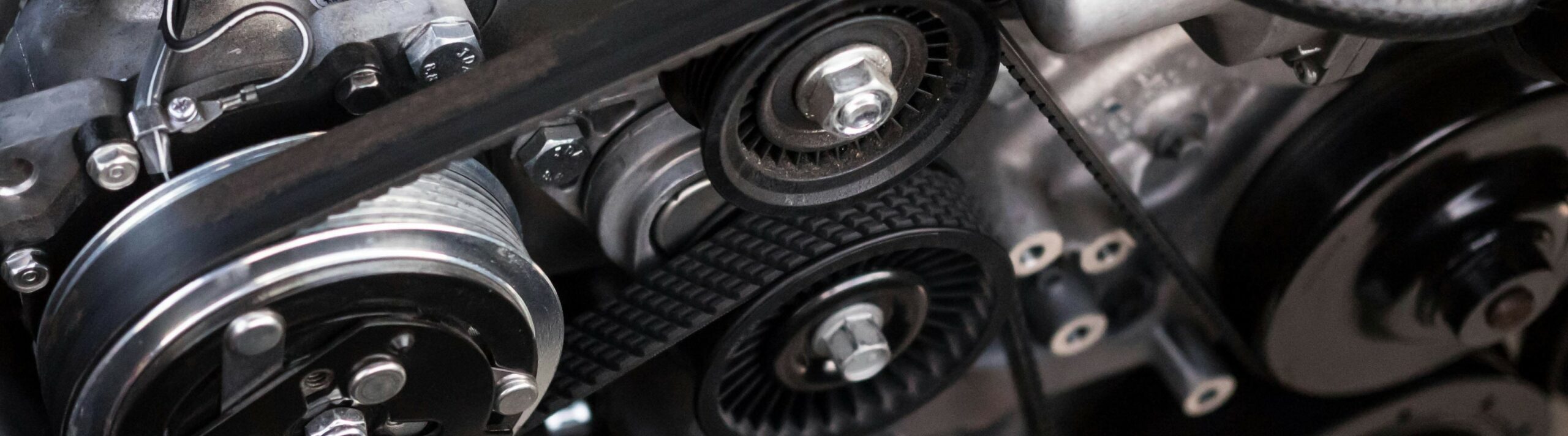

Automotive Manufacturing Excellence

There are thousands of components that make up assemblies and products within a vehicle, and every component plays a role in vehicle functionality. Among these essential components, automotive springs and spring assemblies ensure your vehicle handles, performs, and rides with stability, safety, and comfort.

Automotive spring expertise

At PJ Wallbank Springs, we understand the automotive industry’s demand for excellence in terms of both performance and quality. Our automotive spring assembly solutions are uniquely designed and engineered to achieve each of our customers’ goals. With a legacy of 40+ years, we have been a trusted partner for most original equipment manufacturers (OEMs) and Tier 1 manufacturers in the industry, supporting spring assembly solutions that meet stringent performance expectations.

Why PJ Wallbank Springs?

When you partner with us, you can expect the following:

- Trusted Engineering – Engineering with a focus on the details (so you can spend your time on other critical priorities) to meet automotive industry standards and serve as a partner to each customer and their unique requirements.

- Durability – Our automotive spring assemblies are designed to withstand harsh conditions, heavy loads, and extended operation times, providing long-lasting reliability.

- Performance Enhancement – Improved controllability and functionality compared to alternative spring choices.

- Streamlined Integration – We’ve purposefully designed our automotive spring assemblies for seamless integration into your manufacturing process, optimizing for simplicity and reducing cycle times by installing one assembled component in each application, compared to installing numerous single springs.

Our automotive springs

Our company’s automotive spring assemblies serve a wide array of applications. Some examples of projects we can support include:

- Ride and Handling for a Global Tier 1

- Differential disconnect for North American EV OEM

- Load delivery and packaging spacer for electric axles of a Global Tier 1

- AWD transfer case clutch for North American Tier 1

Automotive Spring Solutions in Action

Spring assemblies impact and support how automotive manufacturers produce top-quality components and vehicles.

Spring Applications for Automotive Drivetrain Applications

Automatic Transmission

Within automatic transmissions, a series of different clutches are engaged or disengaged to allow for the transmission to shift, optimizing engine performance. Each clutch pack comprises a series of clutch plates, a spring pack, and a piston.

When oil pressure is applied within the clutch pack, the piston compresses the spring assembly and engages the clutch plates, enabling that clutch to perform its intended function. When the oil pressure applied to the piston is reduced, which occurs when the transmission shifts, the spring pack releases its stored energy and provides a return force to the piston. This enables the piston to return to its original starting position, thereby disengaging the clutch plates for that particular clutch.

The spring pack also serves a secondary function in rotating clutches by providing a static load against the piston to prevent it from applying the clutch pack due to centrifugal forces, which can cause drag losses.

Transfer Case

Spring assemblies in automotive transfer cases can contribute to the overall functionality of 4WD and AWD vehicles, allowing drivers to adapt effectively to various road conditions and terrains.

Transfer case springs can provide smooth and controlled engagement and disengagement of power distribution to a vehicle’s front and rear wheels.

Differential Disconnect

Spring assemblies can benefit the proper operation of differential disconnects in multiple ways.

When the differential disconnect is engaged, automotive springs assist the actuation mechanism to ensure appropriate power distribution to the wheels.

Spring Applications for Automotive Suspension System Applications

Spring assemblies in automotive suspension systems can serve many purposes. The main purpose of one specific component, the shock absorber, is to ensure the vehicle’s tires stay in contact with the road at all times, allowing for safe control and braking.

The spring assembly within the shock absorber helps it function like a hydraulic pump to control the impact and rebound movement of the vehicle’s springs and suspension, smoothing bumps and vibrations in the road surface.

Spring Applications for Braking System Applications

Automotive springs add longevity and functionality to braking systems. Custom automotive springs are often used for braking systems with unique designs or requirements.

Spring Brakes

Spring assemblies can benefit emergency and auxiliary parking brake systems. They help reliably apply brakes using their compression force.

Spring assemblies can also help maintain a brake’s position without the requirement of pressurized air, making them valuable, especially in situations when there’s pressure loss somewhere in the braking system.

Park-Lock Braking Systems

Spring assemblies in automotive transfer cases can contribute to the overall functionality of 4WD and AWD vehicles, allowing drivers to adapt effectively to various road conditions and terrains.

Transfer case springs can provide smooth and controlled engagement and disengagement of power distribution to a vehicle’s front and rear wheels.